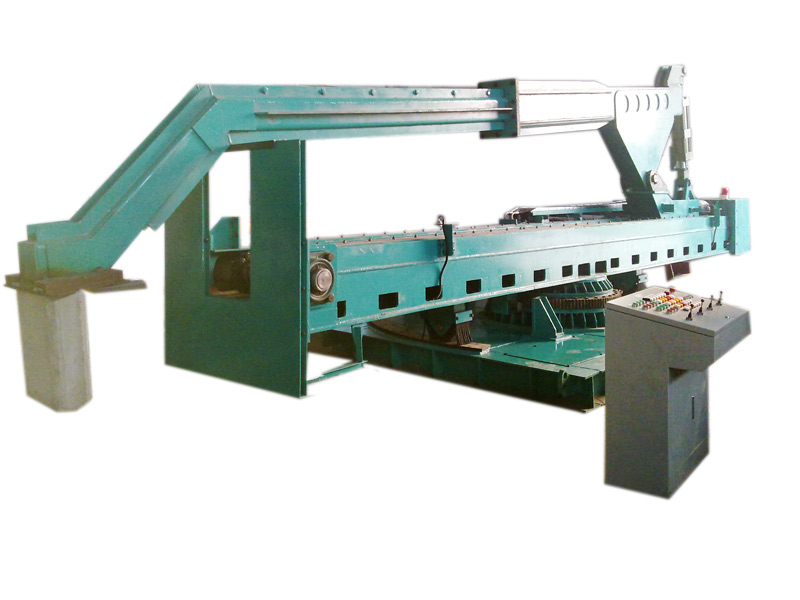

Main purposes of the slag extractor:

Suitable for construction machinery in tunnel excavation, mining engineering, hydraulic engineering, and other projects, as well as small-section water diversion tunnels and mine slag (ore) removal machinery, this machine is primarily used for the collection, transportation, and loading of gravel and soil materials in non-explosive hazardous mines such as phosphate mines and metallic and non-metallic mines where production space is narrow and production scale is small.

Characteristics of slag extractor:

It is a production device that combines a robotic arm and a conveyor, integrating both collection and conveying functions. Utilizing an electric hydraulic control system, it features safety, environmental friendliness, low energy consumption, and high efficiency. It is an essential advanced mining equipment for mines and small tunnels, serving as a substitute for manual labor and other machinery.

Advantages of belt scraper conveyor:

The machine incorporates five functions: hydraulic travel, excavation and collection, conveying, loading, and bottom cleaning. The hydraulic travel function is achieved through a hydraulic motor, a reducer, a transmission shaft, and then a reducer to drive the wheels. The hydraulic motor has three functions: forward movement, backward movement, and automatic braking. The excavation and collection function is performed by a robotic arm, which has the capabilities of excavation, arm extension, loading, and unloading. The boom can ascend, descend, and rotate left and right. The excavation and collection operations are controlled by full hydraulic control, operated by two joysticks, and the operation method is similar to that of an excavator. This technology is comprehensively improved using the operational processes of large excavators, making it convenient to use and easy to operate. The conveying and loading functions are performed by a conveyor system. The conveyor frame is controlled by a hydraulic cylinder for lifting and lowering. When the conveyor frame descends, the front wheels can be supported, and at the same time, the front material receiving port of the conveyor frame is in closer contact with the ore surface, providing greater stability during operation. It can also receive loose materials, level the ground, and has a conveyor belt width of 650-700mm and a conveying speed of 800-900mm/s. The conveyor belt is driven by a 2.2kw motor through a reducer to drive the driving drum. This method provides more stable transmission performance, longer service life, and easier maintenance.