Iron Casting Machine Technical parameters and specifications

I. Description

1. Purpose

This machine is used in the post-process of the cupola furnace - it casts molten iron into continuous small iron ingots.

2. Working principle

The HLL type elastic pin coupling and YWZ brake are driven by the electric motor, which, through the reducer, transmits power to the drum gear coupling. This, in turn, drives the chain belt shaft to pull the chain belt, enabling the cast iron mold to rotate in a circular manner. Molten iron is poured into the cast iron mold, which rotates continuously. During this rotation, water is used for cooling, resulting in small iron blocks. These blocks eventually move to the rear of the machine, flow into a bidirectional tipping bucket, and enter a flat car.

4. Scope of equipment supply

Including: 1) Iron flow channel

2) Equipment in front of the pig machine: cover plate, iron water retaining plate, slag trolley, 300 pulley.

3) Casting machine body: head wheel assembly, tail wheel assembly, head wheel bracket, tail wheel bracket, chain assembly, roller assembly, roller bracket, casting mold, coupling, upper and lower rails, main power motor, main power reducer, main power brake.

4) Metal forging device

5) Iron chute

6) Bidirectional iron block turnover device: including two electric push rods

7) Spraying device: The spraying device is positioned beneath the pig casting machine and employs the current mixing method. No spraying treatment room is required. It includes two slurry pumps (with motors) and one mixer (with motor).

8) Cooling system: including all cooling water pipelines of the on-board part. (Note: excluding water pumps and pump room facilities, circulating water treatment, and later iron block cooling.)

9) Electronic control system.

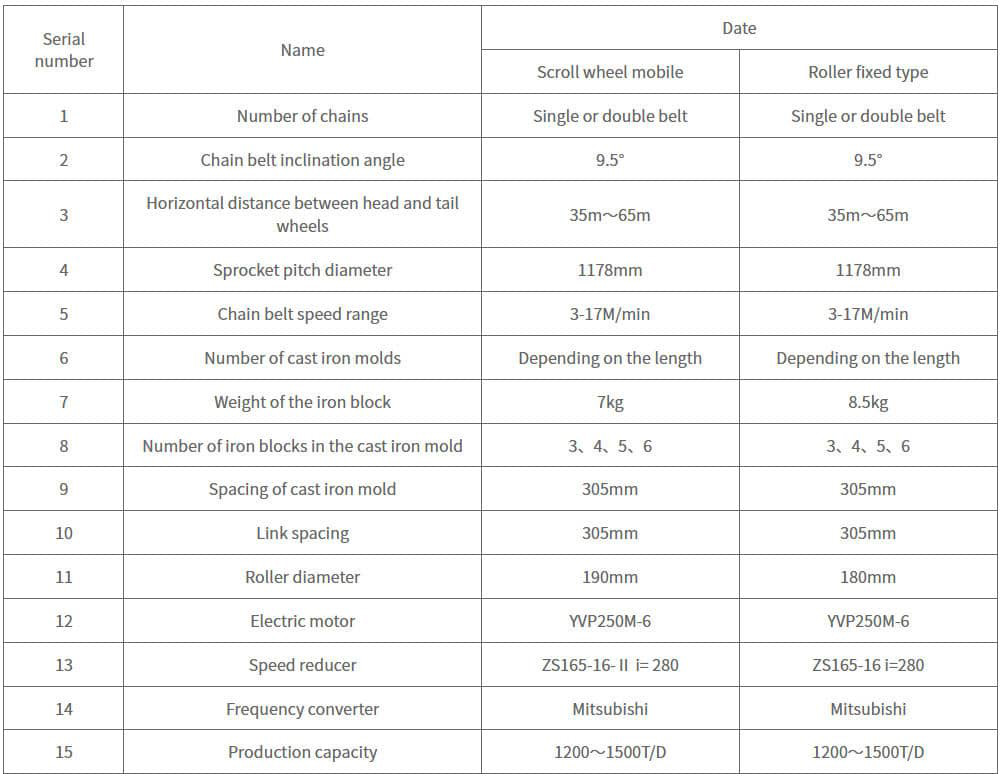

II. Technical Parameters

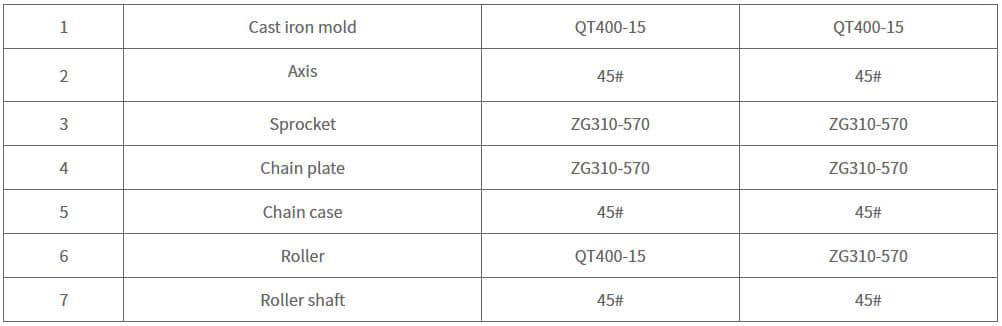

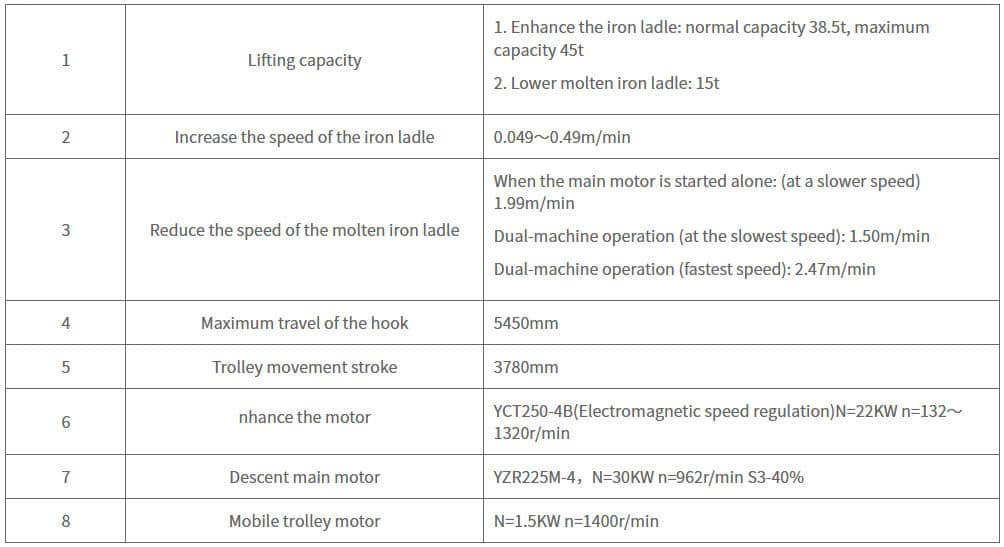

65T tipping and turning

Cast iron machine material